During this early stage of the Chinook's service with the RAF, a small group of pilots were trained at the Boeing Vertol factory in Philadelphia.

Once a large enough group of fully trained instructors had been established, they formed a Chinook flight at 240 Operational Conversion Unit which was responsible for training Wessex and Puma crews.

The Chinook was the first large aircraft flown by a 4-man crew and as a result they based the course structure on the C-130 Hercules OCU. Ab Initio pilots were trained on the Chinook OCU as co-pilots to fly alongside the more experienced pilots. After a short while of 240 OCU running, it was seen how effective the course was and that crews graduating from the course were more than capable of captaining a Chinook on their first day of their new squadron.

Shortly after the HC2 Chinook was phased in, the Puma's relocated from RAF Odiham over to Benson which led to 240 OCU disbanding. The Chinook conversion flight was then embedded into 18 squadron, a structure that is still in place today...

Today, 18 squadron is divided into three flights. A and B flights are the operational flights where as C flight is the Operational Conversion Flight.

The Squadron also has a Headquarters Flight, which all combines to form around 120 personnel which is one of the biggest Squadrons in the RAF today.

The Operational flights (A & B) work in a cycle of duties with 27 squadron's three flights (A,B & C) including detachments, training and stand-by's including National standby. National standby is a crew that is on-call and ready to respond to any incident within the UK at very short notice. This can include accidents/disasters to hostage and terrorist situations. In addition to this, whilst at Odiham crews carry out currency sorties to ensure they stay current on all forms of flying including formation work, confined areas, slopes, NVG's and instrument approaches.

The Operational Conversion Flight (OCF) caters for three groups. A small portion of the 'students' are Squadron Leaders who have completed a desk-job tour and are returning to the Chinook force to take command of a squadron. Another are crews transferring from another aircraft type - both of these groups take a shorter course which is around 3 and a half months.

The majority of the OCF are ab initio students. When joining the flight, they have just arrived from flying the Griffin HT.1 at RAF Shawbury having completed their multi-engine helicopter course.

The objective of today's OCF is to train ab initio pilots and crewmen to a standard where they are able to deploy straight after completing the course whilst using the minimal amount of flying hours, firstly to reduce costs but also to maximise the output of airmen and provide a constant stream of deployable crews.

For the initial part of the course, the new students spend 3 weeks at RAF Benson at the £100million Medium Support Helicopter Aircrew Training Facility (MSHATF) where they make use of the 3 state-of-the-art Chinook simulators. These can be inter-linked with each other along with the two Merlin and single Puma simulator to provide realistic operational missions where they work together. On top of that, the simulator can simulate Forward Looking Infra-red (FLIR), defensive aids and even in-flight refueling!

The advantage of having the multi-simulator MSHATF is that simulator time can be integrated with the ground school and even flying the actual aircraft itself rather than just spending a block time in the simulator.

Clearly, this is the future of Conversion To Type (CTT) training and air crewmen can expect their simulator hours to triple and actual flying hours halved during CTT.

An often over-looked element of the course is learning about the components of the Chinook as part of the pre-employment training.

Both Pilots and Crewmen need to know about the core components of the aircraft, firstly so faults can be quickly diagnosed and rectified but also if the aircraft is forced to land away from the airfield, the crew should have the knowledge to fix basic problems.

Whilst in flight, the crewmen have a panel to the rear of the cabin which monitors the basic systems and also indicates potential problems.

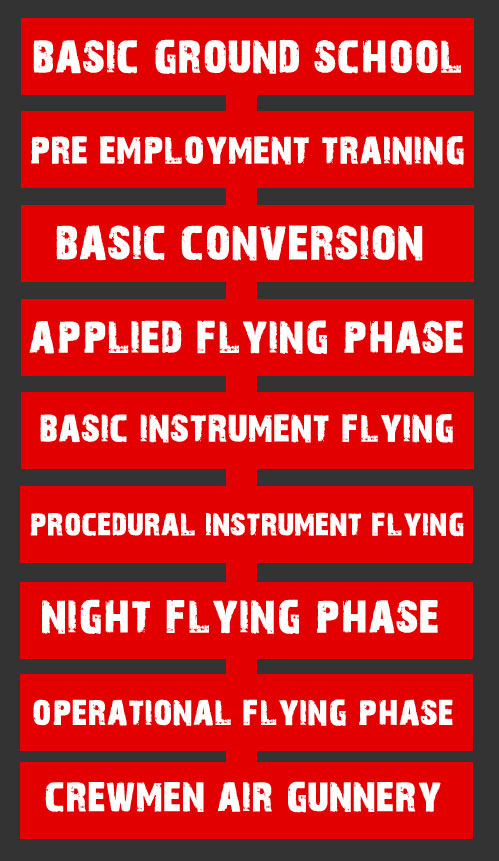

After the lengthy theory work, phase one of the course is to teach the students just to fly the aircraft with the objective of qualifying as 'First Pilot' after just under a month. To get to this stage, the ab initio pilots would have been through this phase, learning to fly the Squirrel and Griffin helicopters. The basic conversion involves 'bread and butter' hovering, flying sideways and backwards and flying the aircraft from one area to another safely. In-flight malfunctions such as having to auto-rotate or losing an engine are also practiced.

The OCF regularly communicate with RAF Shawbury's Multi-engine rotary course suggesting elements they can teach the students so that the conversion is smoother.

Having completed the basic conversion to the Chinook, the students then go on to the Applied Flying Phase. One of the best exercises of this phase is to use confined areas within woods which involves communicating with the crewmen down the back to negotiate obstacles such as power-lines, civilians, animals and trees. As well as the hazard of the trees, the wind can often change characteristics as the aircraft lowers into the clearing, which itself can generate a turbulent column of air which can cause wobbling for the aircraft.

Sloped landings can also be classed as another 'bread and better' skill set to have as a Chinook pilot or even crewman. Perhaps surprisingly, the crewmen have the most work to do when landing on a slope. As well as looking out for obstacles, they have to quite literally hang out of the aircraft and look underneath to check ground clearance and to notify the pilot how far from the ground he is and which wheel is going to be contacting the ground etc. The method for landing on a slope is to lower gently on to the slope until the aircraft has made contact with the ground but is still level with the horizon. The pilot then slowly lowers the collective/power until the aircraft comes to rest.

Another section of the Applied Flying Phase is Under-slung Loads (USL's). This is one of the main duties can expect to be doing whilst deployed so is practiced regularly. Again, a lot of communication and team work is needed from the Crewmen and Pilots.

The OCF makes good use of RAF Odiham's Tactical Load Park (TAC park). Here, Joint Helicopter Support Squadron (JHSS) and the Mobile Air Operations Team (MAOT) provide the 'hookers' to load up the loads to be lifted. The USL training starts with a small water container and gradually builds up to triple loads, artillery gun and even an ISO container!

This is then combined with the confined area training where they hook up an under-slung load and fly to a field location. This sounds basic flying, but the crews have to navigate around residential areas when carrying a USL and flying characteristics change depending on the load and which point the load is hooked onto the aircraft.

Instrument flying is an essential skill to any military pilot. Whether it's bad weather in the UK or dust storms on deployment there will always be situations where crews will need to fly in IMC (Instrument meteorological conditions). This goes from using the Autopilot, which in the Chinook only provides stabilisation, attitude hold and flight director or making Instrument Approaches to airports.

Another element is flying in airways which the OCF uses London's heli-routes straight through the centre of London and up The Thames...

The night flying phase is the final stage of the Conversion to type section. The OCF spend 6 weeks flying at night with the aid of NVG's (Night Vision Goggles) practicing Confined Area training, Under-slung loads, slopes, over-sea flights, instrument flying and anything else that could be needed to be done during the night.

Yet another skill set that will become useful when they deploy is low visibility landings (LVL) otherwise known as Brown-outs. A Brown-out is a term used for landings in dusty areas that impedes the view out of the aircraft which makes it difficult to land.

When the pilot loses references of the ground, the crewmen in the back become their eyes and ears. They call out how high they are from the ground and any potential hazards. There are only a several locations in the UK where this can be practiced so they go to Jordan and USA to practice them in conditions closer to Afghanistan.

The final phase of the course is the 'Operational Flying' phase where they use the Chinook as a platform rather than just flying.

To begin with the 'Op phase' introduces them to tasking's they may experience regularly whilst on deployment. This includes Troop moves on Salisbury Plain (SPTA), Stanford Training area (STANTA) and Sennybridge and under-slung loads at field sites. Tasking's start off simple, for example a USL picked up from field A and taken to field B. As the phase go on the tasking's become more fluid, and new mission's, and obstacles mean they have to re-organise and re-plan whilst airbourne. The latter part of this stage is done whilst on detachment to RAF Leeming. Here they are given grid-references and lat/long's whilst air-bourne and have to plan the tasking and negotiate timings with units on the ground and back at base. This can mean working five different radios, communicating between the crew onboard and planning a route all whilst flying from A to B via C...

The final stage of the OCF, is Aircrew gunnery for the Crewmen.

The majority of the air gunnery is done at Pembrey Sands in South Wales.

The Chinook can carry two M134 six-barrelled Miniguns, one in each front side window, and an M60D machine gun on the ramp.

The M134 minigun can fire an impressive 4000 7.62mm rounds per minute whilst the M60D machine gun can fire 550 7.62mm rounds per minute.

In 1995, 8 variants of the MH-47E Chinook were ordered as dedicated Special Forces helicopters at a cost of £259million due to enter service at the end of 1998. Delivered in 2001, the HC3's airworthiness certificate was refused as it was not possible to certify the avionics software. The avionics were unsuitable due to poor risk analysis and necessary requirements omitted from the procurement contract. Quite famously, the helicopters made frontline news when it was revealed they could only fly in VMC (Visual Meteorological Conditions) so were stored at MoD Boscombe Down. In March 2007 the MoD announced it would revert the HC3's back to HC2 standard at a cost of £50-£60 million which would eventually become almost £500million. On 6th July 2009, the first of the 8 HC'3 made it's first flight at Boscombe Down. Today all 8 are now flying but at the time of writing, still not received their clearance to become operational. As a result they are just used for training in the UK and the OCF in particular make good use of them.

Whilst the HC3 isn't massively different to the older HC2, there are a few distinctive characteristics.

Visually, the HC3 has a longer nose with a black tip which held a radar until the 'reversion process'. Also the HC3 appears wider due to the bigger fuel tanks on both sides. Whilst the HC3 can travel further and longer, the added weight means it can not lift as much. Not so obvious, are the more powerful Lycoming T55-L-714 engines.

As the HC3 has quite a few differences to fly out of the two, those who went through the OCF when the HC2 was used are required to do the ground school followed by two day time sorties and a single night trip before being signed off to fly the Mk3.

In 2009, a £408million project named 'Project Julius' was announced to modify 38 HC2/HC2A and the 8 HC3's. This upgrade will enable the HC3's to go operational. The project will make the HC2's into HC4's, the HC3's will become HC5's and the new build Chinooks on order will be HC6's.

The main upgrade of Julius, is the new Thales TopDeck package which features Multi-function displays that can provide easier onboard mission planning which data can be transferred to/from securely. Primary flight data such as temperatures, fuel and any problems replaces the endless amount of analogue instruments which will ease the crew's workload.

The entire HC2 fleet will have this new cockpit by 2015 with the HC2A's and HC3s completed shortly after.

The modifications also include the addition of a third crew-member seat, upgrades to the Honeywell T55-714 engines and an update of Airworthiness & Safety Certification and Qualification for the modernized Chinook. The engine upgrade boosts performance by 20% and will improve serviceability.